Advanced Heat Exchangers: Design, Operation, Inspection and Troubleshooting

This advanced course covers all design and specification aspects of the different types of heat exchangers. Scientific principles, design principles, standards and industrial practices are presented to the attendants. Thermodynamics leading to design and operating specifications are covered in detail. Materials selection and manufacturing methodologies complete this 5-days seminar. Several optimization examples are included whereas the advantages and shortcomings of different HX are revealed. Novel approaches in manufacturing HX are also presented. Dimensionless numbers and similarity principle are explained in detail so that the attendant develops and understanding of designing HX for complex geometries and transient conditions.

Objectives:

By the end of the course, participants should have:

üAn overview of the related theory of heat [and mass] transport

üAn understanding of operating and maintenance of heat exchangers

üKnowledge of all heat exchangers types and classification

üKnowledge of control and monitoring approaches

üKnowledge of heat exchanger fluids

üKnowledge of sizing and design approaches

üKnowledge of case studies

üHands on calculations

Contents:

üTypes of heat exchangers

üScientific background

üThermodynamic principles

üApplications of heat exchangers

üClassification of heat exchangers

üDesign and sizing

üResistances to heat and mass transfer

üThermal conductivity, overall heat transfer coefficient

üCalculations and examples on heat transfer in various geometries

üCalculations and examples on heat transfer under steady state and transient conditions

üTypes of boundary and initial conditions

üNumerical and analytical solving of sets of differential heat exchange, velocity and momentum equations

üDimensionless numbers and dimensionless graphical approaches

üSimilarity principle

üCombined heat transfer [conduction, convection, radiation]

üCross flow, counter flow, and parallel flow comparison

üExamples and real time work on optimization of HX based on different type choices

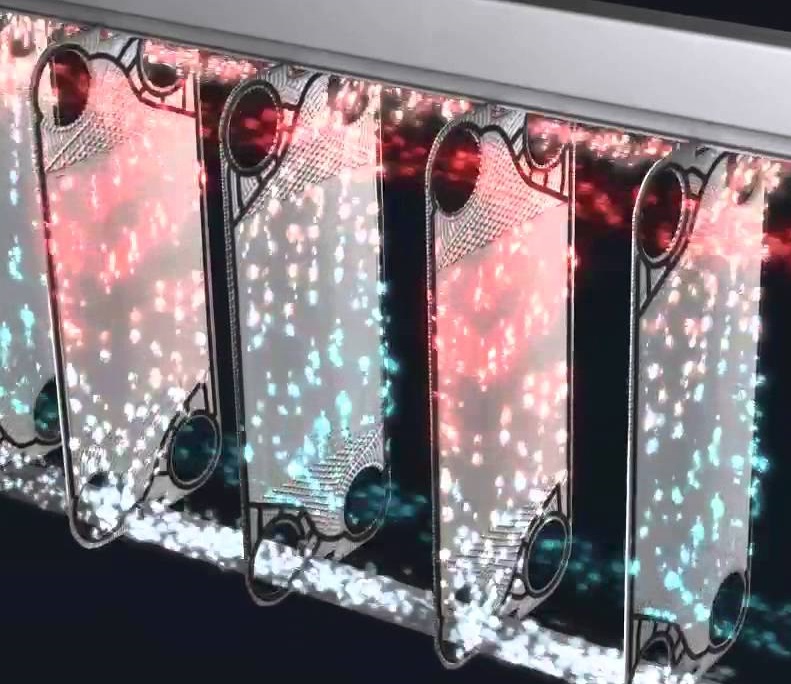

üShell and tube vs Plate HX

üSingle pass vs Multiple pass HX

üIonic Salts, Molten salts and other viscous heat transfer liquids

üCorrosion and erosion in HX

üInspection methodologies [Hydrogen, Hypersonic, pressurization, visual inspection]

üCompact and high compact HX

üNovel HX and novel manufacturing approaches; the atomic continuous approach

üCase studies

üRetrofitting

üControl and monitor

üOperational conditions

üFouling

üIntegration

üSimulation and modeling

Who should attend?

üMechanical Engineers, Chemical Engineers, Process engineers, workers, maintenance staff

üExecutives of oil and gas, chemical, manufacturing and petrochemical industries

üTechnicians and maintenance personnel