Solid Fuels outlook [May 2016]

Coal contributes to around 25% electricity generation in EU and to industrial energy generation for specific applications. Most of European countries exhibit availability of coal deposits which are cheap to use. Up to date, most countries use a combination of various energy sources for electricity generation, with coal being the major contribution for most of them. On the other hand, due to the low carbon dioxide emissions regulations, coal use is reduced on a yearly basis across EU. Countries that cannot meet the set goals on coal contribution limits on their electricity generation balance are fined, as in the case of Greece.

Recent reports have identified India as the only potential large consumer of coal, with a prediction for an additional 900 million metric tons requirement by 2040. Industrialized countries are expected to show stable or decreasing coal demands, irrespective of new technological advances explained below. Thermal coal demand is expected to demonstrate a 7% decrease by 2019. US coal production has fallen by 36% since March 2015. Another 16% decrease in expected within 2016, leading coal production to record lows of production. Overall coal stockpiles increased by 22% last year alone in the US.

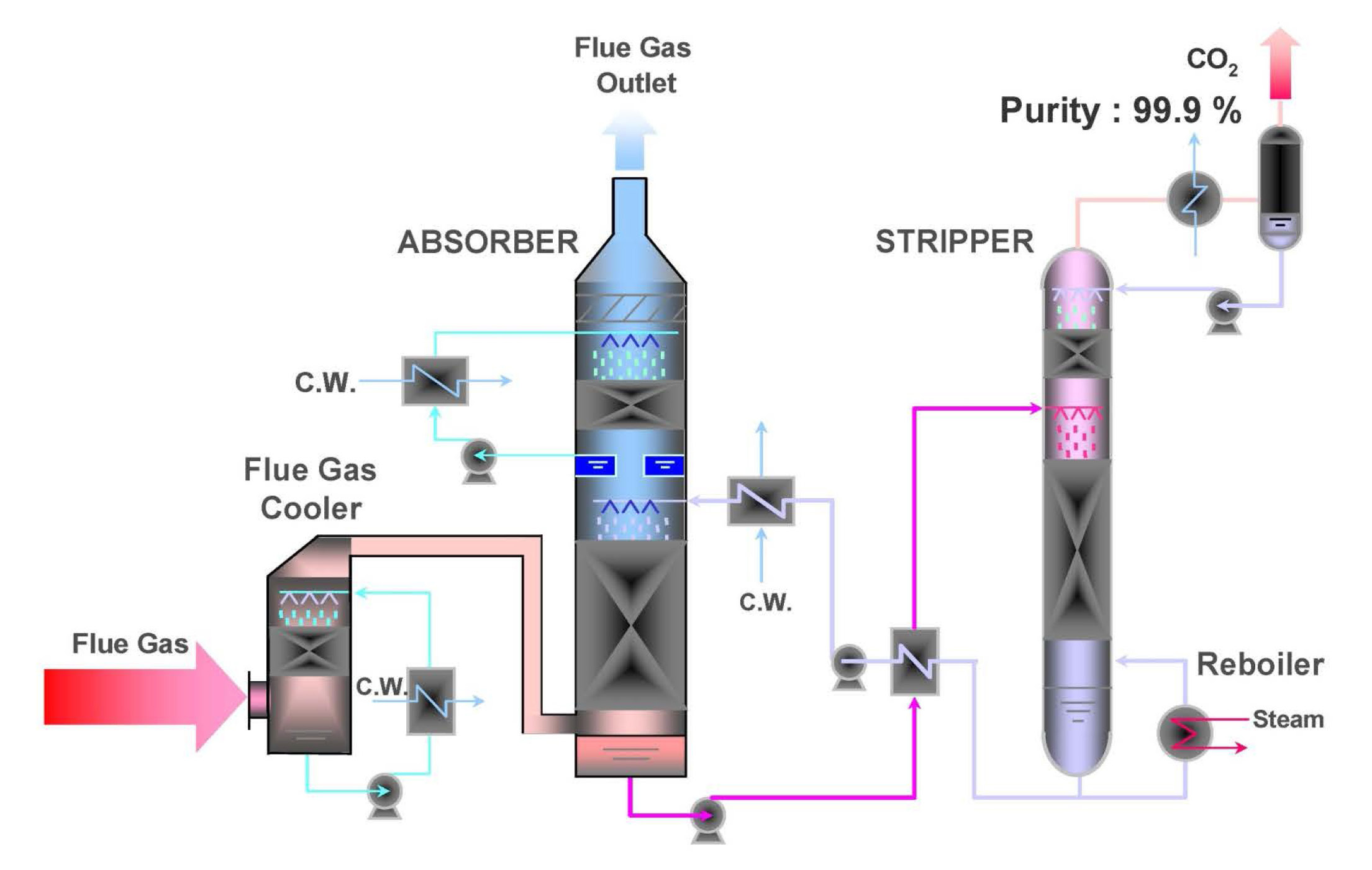

A factor contributing to coal use for energy generation are the advances made in clean burning technologies, both pre combustion and post combustion. Carbon Capture and Storage [CCS] has allowed for increased use of coal species in retrofitted energy plants around the globe. The currently set target is 40$ of captured Carbon Dioxide by the end of 2025. The strategy for achieving this goal that will allow for continuation of coal use as an electricity generator can be analyzed as following:

Ø Development in process chemistry

Ø New chemical production methods

Ø New equipment manufacturing methods

Ø Optimization of process integration with other power plant systems

Ø Advances in boiler and gasifier technologies

Ø Heat integration

Ø Gas clean up and separation

Retrofitting currently operating coal fired power plants has exhibited some disadvantages, including:

- Many carbon dioxide carbon technologies have not been tested to scale

- A 20-30% observed in efficiency of power plants

- Up to 80% higher electricity generation costs

Currently, research on CSS technology focuses on reducing carbon capture and compression costs [DOE]. This can be realized via:

- New materials for capture and separation – ionic liquids, polymeric membranes

- Retrofittable reduction technologies

- Integration of CO2 capture with advanced power cycles and technologies and with environmental control technologies for criteria pollutants

- Development of advanced technologies for CO2 compression such as "shockwave compression."

Oxyfuel Combustion processes use oxygen rather than air for combustion of fuel. This produces exhaust gas that is mainly water vapor and CO2. The exhaust gas has a relatively high CO2 concentration (greater than 80 percent by volume). Oxyfuel combustion represents an opportunity to improve the economics of CO2 capture.

Solvents and Sorbentsfor CO2 separation from flue gas (both physical and chemical) can be further enhanced to reduce cost, improve reaction rates and regeneration loads, and eliminate contamination from other pollutants. This includes technologies such as aqueous ammonia, advanced amines, ionic liquids, metal organic frameworks, and amine-enriched sorbents.

Advanced Membranes for both oxygen-separation and CO2 capture are key enabling technologies. This effort will evaluate needs for advanced membranes applicable to pulverized coal systems and other conventional combustion systems that will minimize the cost and efficiency losses for CO2 separation.

Chemical Looping processes that prevent direct contact of air and fuel offer the ability to produce a relatively pure stream of CO2 that does not need to be separated from flue gas. Technical challenges remain in key areas such as solids handling and oxygen carrier capacity, reactivity, and attrition.

Pre- combustion carbon capture approaches offer significant advantages that allow for the continuation and expanding of coal fired power plants with few disadvantages:

ü Removal of rich CO2 stream after initial oxidation [15-50%]

ü Avoidance of capturing low concentration CO2

ü Current cost at 60$/ ton CO2

ü Disadvantage of higher initial installation costs required

Gasification is the most significant pre combustion approach and it demonstrates unique environmental benefits:

• Extremely low Sox, NOx and particulate emissions

• NOx from the gas turbine is limited to thermal NOx

• Using oxygen instead of air produces a rich CO2 stream that is easily captured

• Valuable by products are obtained and sold

Gasification thus is expected to exhibit an increase in utilization in most industrialized countries with coal deposits, including USA, China and others.