Current gaps in computational chemistry and CFD software packages

Computational chemistry approaches offer capabilities for the prediction of chemical, physical, mechanical and electronic properties that could only be imagined ten years ago. Various methods and approaches allows scientists to predict behavior of chemical, physical and electronic systems with experimental accuracy, taking advantages of advances in the field of theoretical chemistry, computational hardware and cloud technology. Most computational chemistry packages offer parallel processing that allows the simultaneous solving of numerous differential equations and the application of endless trial and error loops. Novel solving algorithms have been integrated into these packages resulting to optimized solving processes with minimum required computational time and extreme prediction accuracy. However, gaps and significant margin for improvement still exist.

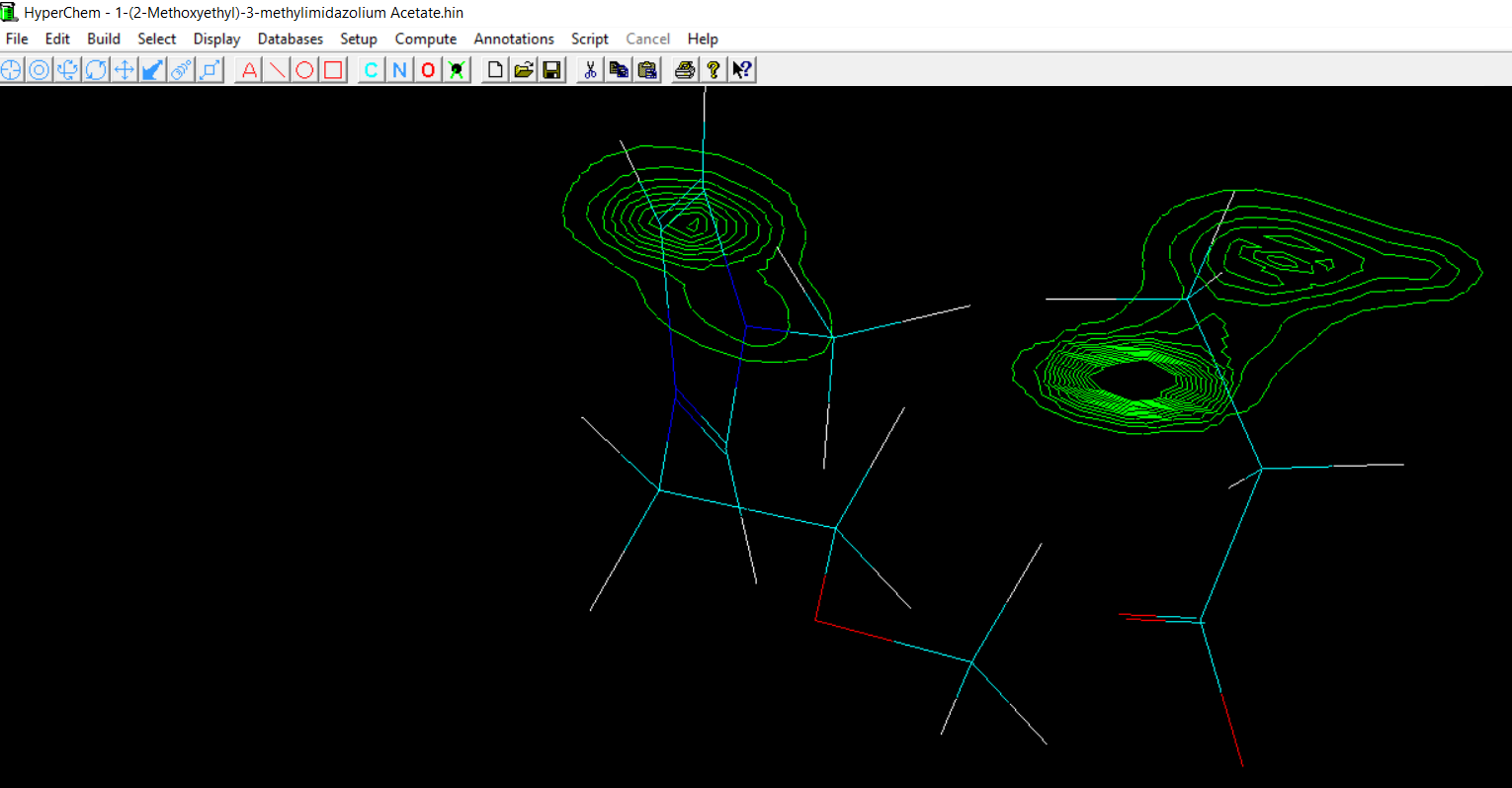

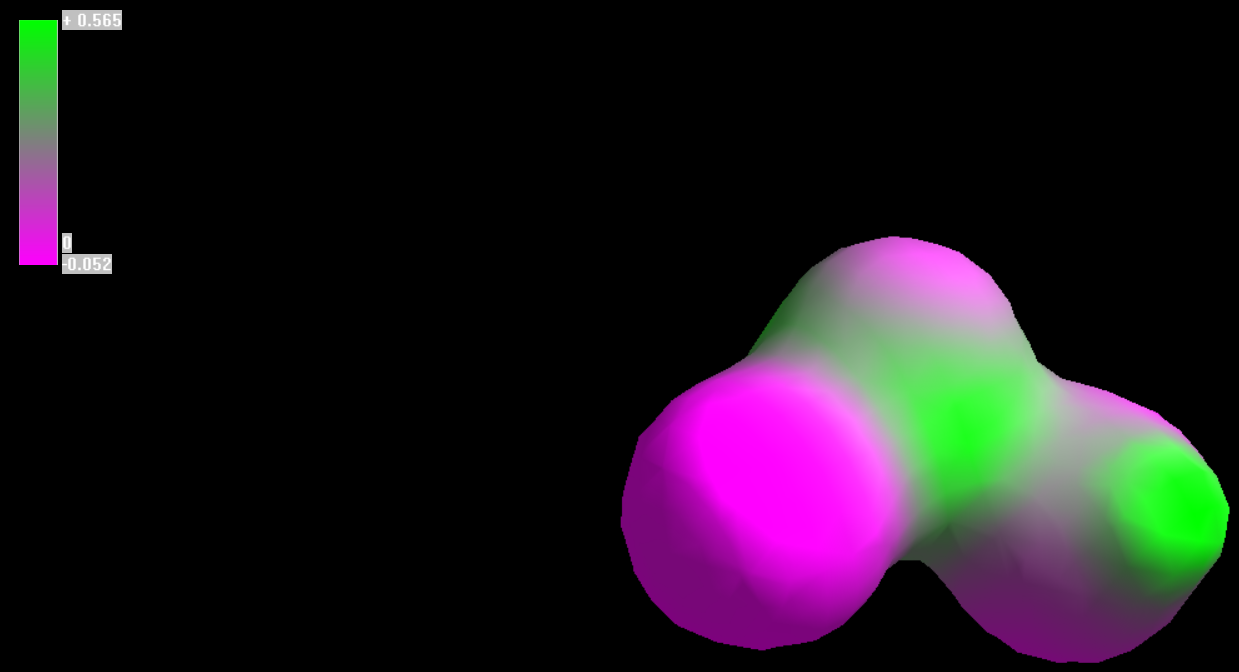

The new challenges in computational chemistry and CFD include mainly their collaboration efficiency; this is the main task that remains partially unsolved. When a material is investigated at atomistic level, its properties can be correlated to micro phenomena such as its molecules distances, their orientation, degree of interactions, stereometric exclusions, increased local affinities and other similar factors. When one is optimizing a known (for example a commercial polymer like PolyEthylene) or a novel compound (such as a functionalized carbon allotrope compound) the material is designed and investigated with absolute accuracy. If this material is then required to be used for the manufacturing of an industrial or electronic part, CFD simulations are the proper computational approach for the prediction of its properties at macro level. Macro level predictions are quite different from those at micro (atomistic) level. When in bulk phase (macro level) all materials exhibit properties that cannot be calculated for single molecules such as mechanical properties (Young’s modulus, tensile strength, etc), thermal properties (a polymer sheet has different degradation temperature range due to increased connectivity, fillers and crosslinking), chemical properties (reactivity, active centers distribution and availability), and electronic properties.

Most CFD (if not all!) software either uses pre-built properties databases for known materials or allow for insertion of values by the user, or both. However, due to these methodologies, the actual microscale phenomena are not ‘live’ when conducting the CFD simulations since they use static values of properties and they do not allow for monitoring of effects at micro scale. One great example of this case is one of our previous projects, dealing with orientation of PE chains at micro level in order to increase thermal conductivity at macro level (application level) (see the link: http://www.sinodoschemistry.com/portfolio/282-enhancing-mechanical-and-molecular-properties-of-composites-via-orientation-at-atomistic-level) . In this case, the micro models have been prepared at atomistic level, and molecular dynamics simulations of orientation of PE chains under external fields have been run. The results provided us with the required lengths, times, external field strength, concentrations of PE and filler in order to achieve excellent orientation of PE chains. For the calculation of thermal conductivity however, one needs to perform simulations of a large segment of this environments, and ideally on macro level. If one tries to set up such a simulation in some of the most powerful and expensive CFD packages available, will soon realize that the connection is static; you can use the optimized properties of micro simulations (in the best case scenario) or you can just pick a material that closely resembles your findings. Thermal conductivity depends on a number of factors such as scattering at the end of chains, phonon transport, electron transport, holes transport; all of these factors are a function of the micro level (atomistic level) simulations! Contacting the producers of major CFD and chemical simulation software will convince you about the difficulties in performing a thermal conductivity prediction for a novel compound. As a first step, approximations and approaches have been added especially to solid chemistry packages, allowing for a first step towards full CFD – molecular simulation coupling.

Understanding that this is a very fine point that is only perceived by the experts, it is suggested that the next step in CFD approaches should be a dynamic linkage with micro scale models and why not, the ability to include micro scale models in CFD that come from molecular model building and simulation. These 3D models (atoms, molecules, ions, or group of any of them) could be transformed into the dynamic set of properties that allow for each level (micro, macro) to reflect on the other. Again, keep in mind that this suggested link will improve accuracy of CFD predictions but its importance is a bit unclear for the non expert. Hopefully next generation of CFD and molecular modeling will be coupled, offering new tools for the theoretical scientist.